How Does the Waste PV Panel Recycling Machine Work

Though discarded photovoltaic panels appear structurally complex, all materials can be systematically disassembled layer by layer and recycled using specialized machine. The first step in the recycling line involves disassembling intact modules. Equipment sequentially separates the frame, busbars, power box, and backsheet. The aluminum frame is removed in one piece via automated cutting equipment, while the backsheet and wires are detached using either mechanical or manual methods, depending on operational conditions. This process prioritizes the recovery of high-value aluminum and clean, independent components, providing standardized processing dimensions for subsequent crushing operations.

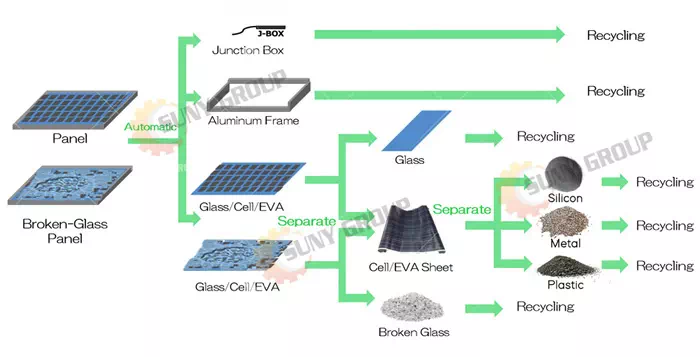

Photovoltaic Panel Recycling Process Flow Chart

Crushing and Glass Removal

Disassembled modules enter the crushing section, one of the core processes in the entire PV recycling line. The crushing system comprises heavy-duty crushers, enclosed conveying equipment, and dust collection systems, rapidly reducing the multi-layered module structure into granular particles. Tempered glass naturally separates during crushing and is extracted separately via vibrating screens and air classification equipment. The resulting crushed glass is clean, uniformly sized, and can be directly used as recycled glass raw material. The crushing section is typically fully enclosed to prevent dust dispersion while maintaining consistent particle size, creating optimal conditions for subsequent metal and silicon material recovery.

Solar Panel Recycling Machine Structure Diagram

Deep Sorting

Crushed materials are conveyed into the sorting zone. PV recycling equipment typically employs multi-stage physical sorting technologies, including magnetic separators, eddy current separators, density sorting tables, and electrostatic separation equipment, to progressively separate different materials. Copper powder and solder ribbons are recovered through the metal separation system. Silicon materials undergo further processing via air classifiers and fine grinding systems to produce high-purity silicon powder, while plastic fragments are extracted through density separation. The entire process requires no chemical solvents, representing a typical environmentally friendly physical recycling method. The final outputs—silicon powder, copper powder, aluminum materials, and plastics—can be utilized in smelting, construction materials, chemical industries, and other sectors, possessing significant market value.

Modern PV panel recycling production lines not only address the large-scale processing of waste photovoltaic modules but also provide reliable support for resource regeneration and green industrial chains. If you are seeking capacity configurations, detailed solutions, or quotation information for complete PV recycling equipment, please feel free to contact us anytime for professional support.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231