Glass Recycling Machine Laminated Glass Separator

Automotive windshields have long been considered the toughest nut to crack in glass recycling. The reason is simple: they contain a tough PVB interlayer that conventional crushing methods struggle to separate. This process is labor-intensive and yields little usable material, leading the industry to dismiss such glass as “non-recyclable long.”

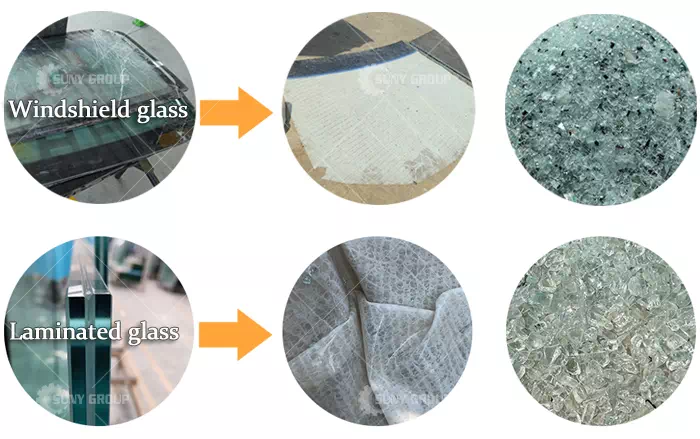

However, the advent of specialized PVB laminated glass separation equipment has completely overturned this perception. With dedicated machinery, waste windshields can be efficiently dismantled, yielding high-purity glass cullet and reusable PVB film, significantly boosting recycling profitability.

Glass Recycling Machine Laminated Glass Separator

Equipment Composition and Process

The complete laminated glass recycling system comprises three components: a glass pre-press, a PVB glass separator, and a dust removal system.

The glass pre-press applies stable compression to distribute stress evenly across the laminated glass, controlling cracks within manageable limits and creating optimal conditions for subsequent separation.

Entering the core stage—the PVB glass separator—the equipment employs a separation structure specifically designed for automotive windshields. This efficiently separates the glass layers from the PVB film. The separation process is smooth and controlled, preventing secondary glass breakage and improving the uniformity of particle size in the resulting cullet. Simultaneously, the separated PVB film retains high integrity, facilitating cleaning, reprocessing, or sale as recycled raw material.

An integrated dust extraction system continuously removes particulates throughout the process, maintaining a clean operating environment, reducing worker exposure risks, and ensuring more stable material quality. The coordinated operation of these three machines enables rapid processing of large volumes of waste windshields, making it particularly suitable for recycling plants, vehicle dismantling facilities, and recycled material processing enterprises.

Turning Waste into Treasure

The separated products are highly refined: one stream consists of glass fragments ready for direct recycling furnaces, while the other comprises reusable PVB film. Both have established commercial recycling channels, transforming traditionally “worthless waste” into genuine profit streams.

For businesses seeking to expand recycling operations, boost production capacity, or enter the automotive dismantling sector, such equipment offers more than efficiency gains—it opens a new revenue stream. Selecting the right PVB laminated glass separation system transforms waste into resources and resources into profits.

For pricing details, additional specifications, or production line configuration solutions, feel free to contact us anytime.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231