Key Processes and Equipment for Lithium Ion Battery Recycling

The rapid growth in the number of used lithium batteries and their widespread application also presents a double challenge of environmental pollution and resource waste. Lithium batteries contain a large number of valuable metals such as lithium, cobalt, nickel, manganese, etc. Scientific recovery not only has economic value but is also a key link to realizing resource recycling.

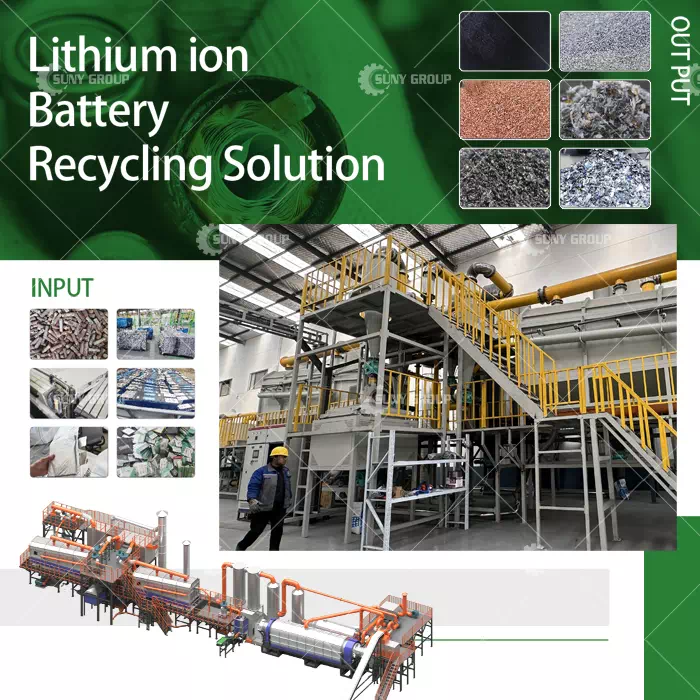

The overall process of lithium battery recycling

The recycling process of lithium-ion batteries is generally divided into three stages: pretreatment, material separation, and metal purification. The overall goal is to achieve efficient and safe recycling of key metals in the battery while reducing secondary pollution of the environment. The entire process requires a variety of specialized equipment to work together to ensure a stable process, high recycling efficiency, and good quality output.

Key Processes and Equipment for Lithium Ion Battery Recycling

Recycling target and main materials

The core of lithium battery recycling lies in the extraction of key metal materials, mainly including lithium, cobalt, nickel, and manganese, as well as aluminum, copper, graphite, and so on. These materials not only have high recycling value but also can be reused in the production of new batteries to alleviate the shortage of upstream raw materials, which is of strategic significance.

Pre-treatment stage technology and equipment

Pre-processing is the first step of lithium battery recycling, mainly including discharge, disassembly, and crushing. In terms of safe discharge, commonly used equipment includes brine pools and electronic load discharge systems to ensure that the batteries do not short-circuit or burn in subsequent operations. The crushing segment crushes the battery shell and internal materials through specialized crushers to prepare for subsequent separation. This stage requires high operational safety and stable processing efficiency.

Material separation process and equipment

After the initial crushing, it is necessary to separate the different types of materials. Physical separation processes are widely used in actual recycling. Magnetic separators are used to remove ferromagnetic materials, while sieves and gravity sorters classify materials according to particle size and density. Through this equipment, components such as copper, aluminum, graphite, and positive and negative electrode powders can be effectively separated to improve the recovery rate and purity of resources.

The lithium battery recycling process requires a high level of equipment to ensure processing efficiency, as well as to take into account safety and environmental protection. Advanced equipment can improve the automation level and resource utilization of the whole production line, and at the same time reduce operating costs. We are committed to providing customers with professional equipment and technical solutions covering the entire process of discharge, crushing, sorting, and heat treatment. Please feel free to contact us for your equipment procurement or production line planning needs.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231