Pharma Blister Packing Recycling Machine

Blister Packing is widely used for solid pharmaceutical packaging due to its good sealing, portability, and moisture resistance. The efficient recycling of aluminum and plastic materials not only helps to reuse resources but also brings considerable environmental and economic benefits. In this article, we will introduce the solutions and technical principles of blister packaging recycling equipment for users with raw material or recycling needs.

The working principle of pharmaceutical blister packaging recycling machine

The pharmaceutical blister packaging recycling machine converts waste pharmaceutical packaging, which contains aluminum and plastic, into reusable aluminum powder and plastic through a series of mechanical and physical processing steps. The whole process is highly automated and stable in operation, which can effectively separate the materials and improve recycling efficiency.

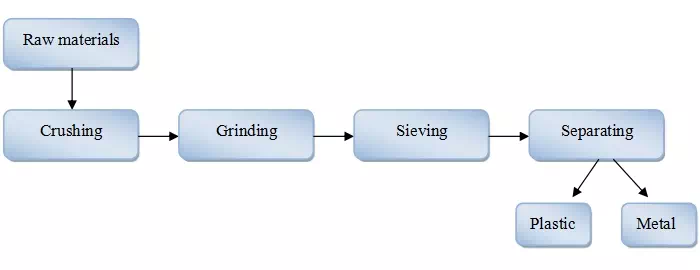

The process flow is as follows:

Feeding → crushing and grinding → electrostatic sorting → product collection

Aluminum Plastic Separator Flow Chart

This process not only realizes efficient dissociation and sorting of materials but also reduces manual intervention through an intelligent control system, making the whole recycling process more efficient and environmentally friendly.

Key technical equipment:

Shredder: It is used to initially crush the whole piece or large piece of waste in blister packaging to a particle size suitable for subsequent processing to ensure the effect of subsequent grinding.

Grinding machine: to further crush the crushed materials to finer particles, which helps to improve the precision and efficiency of electrostatic sorting.

Electrostatic sorting equipment: as the core link, this equipment can accurately separate aluminum powder and plastic powder, with a high sorting rate, stable operation, and easy maintenance.

Pulse dust removal machine: In the whole production process, it can effectively control dust spillage and ensure a clean operation environment and the durable and stable operation of the equipment.

Equipment selection:

Different users should choose the appropriate equipment model according to the raw material form (whole blister or scrap), capacity scale, and plant layout. For example, pharmaceutical manufacturers have a large amount of waste products, it is recommended to use high-capacity automated models; while small and medium-sized recycling sites can choose a compact unit with a small footprint and easy operation.

Application Scenario:

This type of equipment is widely used in the recycling workshop of pharmaceutical manufacturers, and environmental resource treatment enterprises. For example, after the introduction of this equipment, a large pharmaceutical company has successfully realized the closed-loop management of blister packaging recycling, which not only reduces the cost of waste disposal but also sells aluminum powder as a renewable resource, obtaining considerable economic benefits.

We have more than ten years of industry experience and many customer cases, to provide pharmaceutical blister packaging recycling equipment trial service and personalized configuration plans, welcome raw material sources, or environmental protection project needs of enterprises to contact us to obtain detailed information and quotation support.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231