Solar Panels Segregation and Separating Machine

As a large number of solar panels reach the end of their service life and enter a peak phase of decommissioning, relying solely on simple crushing or landfill disposal not only wastes resources but also transforms green energy into a new environmental burden. The solar panel separator developed by SUNY GROUP can dismantle, separate, and recycle these structurally complex solar panels, returning materials to the industrial system—this is precisely the purpose of solar panel sorting and separation equipment.

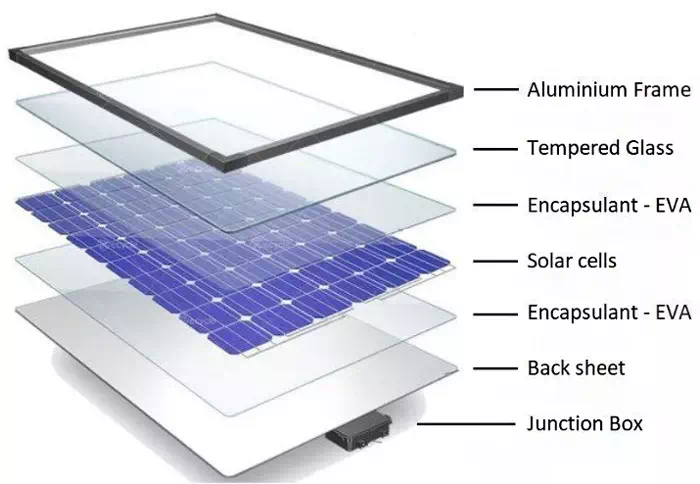

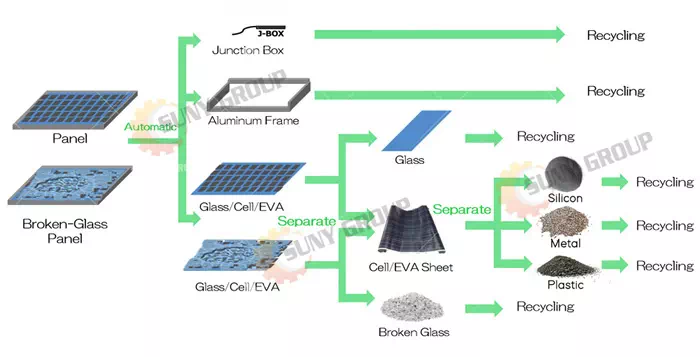

A complete solar panel may appear to consist solely of glass and a frame on the surface, but internally it is a multi-layered composite structure containing tempered glass, aluminum frames, silicon solar cells, metal conductors, and various encapsulation materials. Mixed processing yields only one result: diluted recycling value and sharply increased back-end processing costs. The core logic of solar panel separation equipment lies in mechanically disassembling this “blended value” at the front end, returning each material to its appropriate recycling channel.

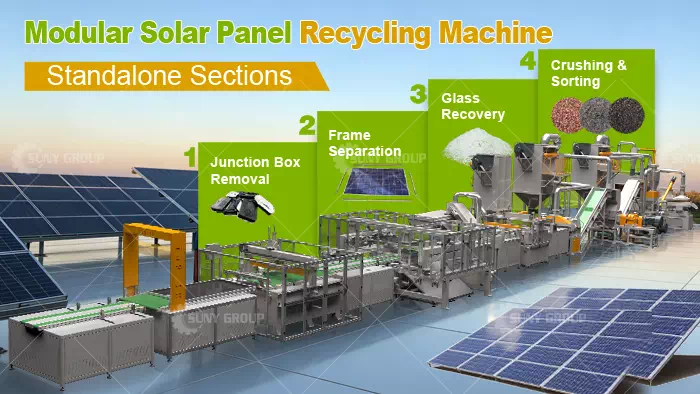

In actual operation, the entire system avoids crude crushing. Instead, it operates around the principle of “controlled fragmentation + efficient separation.” After entering the system via a continuous feed mechanism, solar panels undergo structural fragmentation by high-strength, wear-resistant cutting units. Fragmentation size is precisely controlled to disassemble laminated structures while preventing excessive mixing of metals and glass. Subsequently, materials with differing physical properties are sequentially separated in the sorting system. Glass, metals, and silicon-based materials enter independent collection units, preparing them for further processing or direct reuse.

The core advantage of this sorting and separation method lies in its stability and scalability. When processing large volumes of retired PV modules, the equipment maintains continuous high-load operation with consistent throughput. It eliminates manual disassembly and avoids frequent shutdowns for adjustments due to module size or model variations. For companies genuinely entering the PV recycling industry, this translates to predictable production capacity, quantifiable recycling revenue, and lower long-term operational risks.

Economically, solar panel sorting and separation equipment functions not as a cost center but as a value amplifier. Effectively separating glass, aluminum, and silicon materials achieves higher purity, enabling clearer sales or reprocessing channels and yielding significantly higher recycling prices compared to mixed material processing. Environmentally, it enables truly closed-loop recycling for end-of-life solar panels.

More importantly, through professional sorting and separation equipment, solar products not only remain clean during their usage phase but also retain their environmental attributes and high-value recyclability at the end of their lifecycle.

With the continuous growth of global photovoltaic installed capacity, solar panel recycling is no longer a future concept but an emerging reality in the market. If you are interested in or require solar panel separation equipment, please feel free to contact us anytime for more information.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231