Why Choose Our Lithium Battery Recycling Machine?

Developed by SUNY GROUP, this industrial-grade lithium battery recycling processing machine employs an advanced “mechanical crushing + precision sorting” process to achieve nearly 100% efficient recovery of copper, aluminum, black powder, and various metal casings from waste batteries.

This article will focus on dissecting the sophisticated process flow of this equipment, exploring how it transforms complex waste batteries into high-purity industrial raw materials.

Lithium Battery Recycling Machine Structure Diagram

I. Core Process Flow: Multi-Stage Separation and Graded Recovery

Unlike traditional pyrometallurgical gold extraction, this system employs purely physical mechanical sorting. This approach not only reduces energy consumption but also effectively preserves the chemical properties of materials, facilitating subsequent recycling.

1. Primary Shredding and Safety Pre-treatment

Battery packs or cells first pass through a heavy-duty dual-shaft shredder. This equipment features live-battery shredding technology, enabling controlled disintegration of entire batteries. The primary objective here is to disrupt the battery's structural integrity, laying the groundwork for subsequent precise material separation.

2. Pyrolysis Process

This is the critical step ensuring separation purity. Shredded materials enter a pyrolysis furnace. Through precise temperature control, the electrolyte within the batteries is vaporized and then condensed for collection. This process not only eliminates safety hazards associated with volatile organic compounds (VOCs) but also reduces adhesion between active materials (black powder) and current collectors (copper/aluminum foil), thereby significantly enhancing subsequent stripping success rates.

3. Hammer Milling and Fine Grinding

The dried mixture then enters a hammer mill and a specialized grinding system. Under high-speed impact and grinding, the positive and negative electrode materials (black powder) are completely detached from the copper and aluminum foil surfaces. At this stage, the material presents as a mixture of particles with varying sizes and shapes.

4. Multi-Gradient Sorting System

Magnetic Separation: Utilizing magnetic attraction, this process prioritizes the separation of ferromagnetic metal casing fragments such as iron and nickel.

Airflow Separation: Lightweight plastic separators and fibers are precisely extracted by airflow based on density and air resistance differences.

Vibrating Screen and Gravity Separation: This is the core process for copper-aluminum separation. Leveraging the density difference between copper and aluminum, combined with high-frequency vibration and gravity separation principles, granular copper and aluminum are collected separately, achieving purity exceeding 99%.

II. Dual Environmental and Safety Assurance

Nitrogen-Protected Explosion Prevention: A closed-loop nitrogen circulation system is integrated into the crushing process, maintaining an inert environment through real-time oxygen content monitoring. This eliminates explosion risks caused by battery short circuits or sparks at the source, ensuring round-the-clock safe production operations.

Machines that Produce Nitrogen

Dust Control: The entire system operates under negative pressure and is equipped with a pulse dust collection system, ensuring no dust escapes the production workshop.

Exhaust Gas Purification: To address electrolyte odors, the system integrates a spray tower and activated carbon adsorption unit, with emissions strictly complying with international environmental standards.

III. Economic Value of Recycled Products

After processing through this system, the outputs are clearly defined and possess significant commercial value:

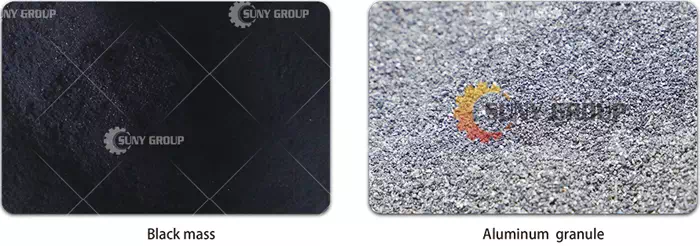

Black Mass: Rich in lithium, cobalt, nickel, manganese, and other rare metals, it is a coveted raw material for hydrometallurgical enterprises.

Copper/Aluminum Particles: Can be directly fed into smelting furnaces for recycling.

Housings and Plastics: Enable resource recovery of waste plastics and scrap iron.

SUNY GROUP's lithium battery recycling machinery is not merely a mechanical assembly, but a precision system integrating materials science, fluid dynamics, and automated control. It transforms the challenging “end-of-life lithium batteries” into sustainable “recycled resources,” providing robust technical support for the closed-loop green energy industry.

For further details, please feel free to contact us anytime to request additional information.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231