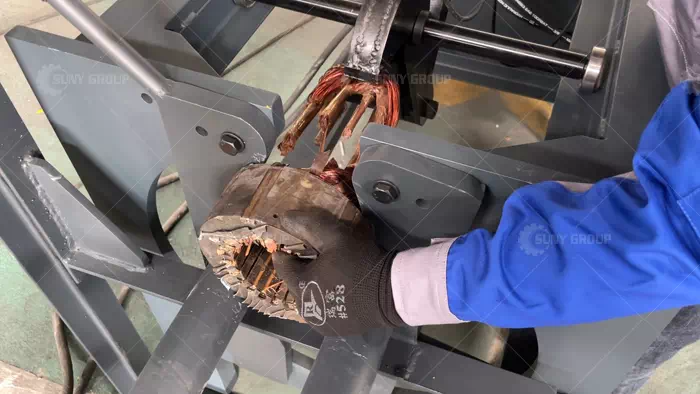

Stator Coil Removal Machine

During motor recycling, stator coils contain high copper resources, but manual disassembly is inefficient, labor-intensive, and poses safety risks.

Addressing this industry challenge, SUNY GROUP's Stator Coil Removal Machine is specifically designed for stripping and recycling stator coils from various motors. Through coordinated mechanical and hydraulic systems, it achieves rapid and complete removal of stator copper wires, providing motor recycling enterprises with a more efficient and stable solution.

This equipment is primarily suited for dismantling stators from three-phase asynchronous motors, home appliance motors, and other motor types. During operation, the machine first secures the stator via a stable positioning structure. Next, the cutting component precisely removes copper wires from one end of the stator, preparing it for subsequent wire extraction. Following the cut, the hydraulic system activates. Through the coordinated action of the wire-pulling and wire-gripping mechanisms, the copper wires within the stator core are extracted rapidly as a single unit. The entire process is seamless and efficient, ensuring high dismantling productivity and excellent copper wire integrity.

Structurally, the machine comprises core units including the main frame, lifting components, wire-cutting components, wire-pulling components, wire-gripping components, electrical control system, and hydraulic system. Each module has a clear division of labor and a rational structural layout, ensuring operational stability while significantly enhancing equipment safety and reliability. Operators only need to perform simple settings to complete the dismantling task, requiring minimal operational experience and making it suitable for long-term continuous use.

Workers Operating a Stator Coil Removal Machine

Notably, the equipment is equipped with two different specifications of wire removal components. Users can flexibly select the appropriate dismantling components based on the size and structural differences of the stator. This design enhances adaptability, covering diverse stator recycling needs across motor types while reducing the additional investment required for equipment replacement.

In practical applications, the Stator Coil Removal Machine significantly reduces manual labor intensity, increases processing capacity per unit time, and improves copper wire recovery quality, creating greater value for subsequent sorting and reuse. For motor recycling enterprises seeking to enhance automation levels, reduce labor costs, and improve recycling efficiency, this is a professional piece of equipment that balances practicality and cost-effectiveness.

For detailed equipment specifications, configuration options, or pricing information, please contact us. We can provide tailored equipment recommendations and comprehensive solutions based on your recycling scale and material characteristics.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231