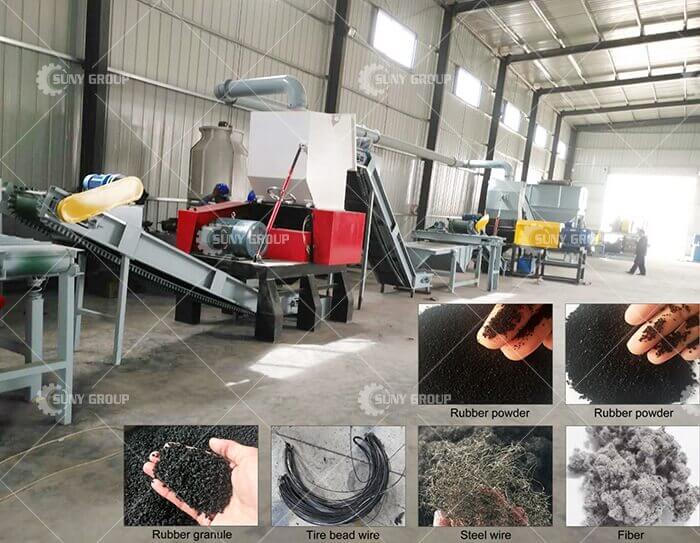

Characteristics of tire crushing and recycling production line

The tire crushing and recycling production line adopts a modular design, which can add or reduce production links on its basis, enhance the flexibility of the production line, and better meet the changing requirements of production capacity and tire types. We truly understand the production needs of our customers, accurately plan and assemble a variety of equipment, and provide a series of high-yield, high-efficiency tire recycling production programs.

For different tire characteristics and productivity requirements, the production line structure may include:

● Fully automatic wire drawing machine: remove tire rim

● Conveying equipment: conveyor belt, screw conveyor and air pressure transmission system

● Shredder: shred tires into film (50mm-150mm)

● Steel wire separator: separate rubber and steel wire and process them into rubber particles (10mm-20mm),

● Magnetic separator: separating steel wire from rubber steel wire mixture

● Crusher: crush the rubber particles to a smaller size (1mm-7mm)

● Vibrating screen: sorting rubber particles of different sizes, and sending the oversized particles back to the crusher for secondary crushing

● Fiber separator: remove foreign matter and fibers

●Secondary magnetic separator: remove the small steel wires that may be left in the place

● Pulverizer: Grind the particles into powder (30 mesh-100 mesh)

● Fully automatic bagging system: the finished product is loaded into storage bags or packaging bags

Features

● The whole tire is placed directly without the need for pre-crushing and pulling the rim

● From the entire tire to 1-7mm pellets, the whole process of production and packaging, without secondary handling intermediate links

● The maximum processing capacity is 5000kg/h, and only 7 people at most can complete all on-site operations

● Configure equipment model according to customer's output requirements, 200kg/h—5000kg/h, wide selection range

● The fully-combined two-layer structure makes installation, replacement, overhaul and maintenance more convenient and safer

● Seamless connection, full dust and smoke monitoring

● Adhere to the 80-100 hours feeding experiment before the single machine leaves the factory to ensure stable performance

● CE certification, unified standards and focus on craftsmanship

test

Before leaving the factory, we will assemble all equipment into a production line and simulate actual use conditions for testing to ensure the production line's capacity and product quality. We sincerely invite customers to visit the operation of the equipment and receive relevant operation and maintenance training.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231