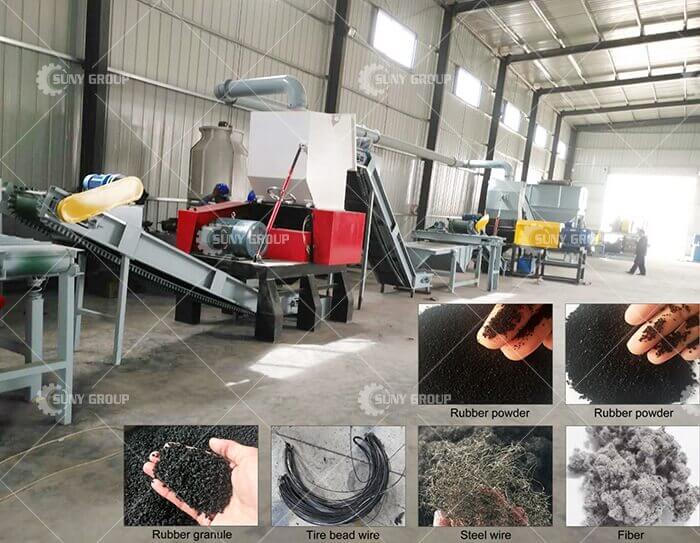

Waste tire production recycling line

The working principle of waste tire recycling production line, waste tire recycling production line is also called waste tire crushing recycling line, waste tire rubber powder recycling line. The waste tire recycling production line is composed of various types of heavy equipment. It can realize the fully automated separation of car tires, truck tires, engineering vehicle tires and the recycling of rubber, steel wire and fiber materials among waste rubber products.

It adopts a structure design that combines a double-shaft shearing crusher and an annular roller screen with high crushing efficiency. It is a necessary equipment for the pre-crushing and pretreatment of waste tires in the reuse.

Waste tire recycling production line 3E Lianguan's waste tire recycling line is one of the few in China that has obtained the European Union CE certification and meets high-standard quality certification. This recycling line can recycle tires within the diameter range of 400-mm according to customer requirements, with strong applicability, the output size can be controlled within the range of 5-100 mm, and the output can reach 200-kg/h.

A complete tire shredder production line processes waste tires and waste miscellaneous rubber at room temperature. The equipment is equipped with a wind-water cooling system, a micro-dust removal device, an atomizing spray system, etc., and an independent dust removal and fiber removal equipment can be added according to the user's special raw materials. .

The tire rim is removed, and rubber particles are obtained by breaking the steel wire and fiber separation. Application of fine rubber powder complete production line equipment: Cut the tire steel hole, and cut the tire into tire rubber blocks. XKP series rubber breaker equipment use: Used to directly crush tire blocks and other waste rubber products into 15-30 meshes. Rubber powder.

The basic assembly of the Jeep waste tire disposal production line is completed, and the workers are intensively debugging and optimizing the work. After the waste tires are crushed and sorted through the waste tire disposal production line, they directly enter the tire cracking and oil refining equipment to decompose the waste tires into steel wire, carbon black and fuel oil to solve the black pollution. This not only creates green economic benefits, but also promotes local Environmental protection construction process!

The intelligent double-shaft motor shear crusher has the characteristics of low speed and large torque, which can crush various sizes of waste tires and ensure the long-term stable operation of the equipment; the cutter adopts European imported high-alloy steel, and the double row can be disassembled and exchanged. The design of the knife structure improves the...

Functional characteristics of the engineering tire crushing and recycling production line: 1. Direct feeding of the whole tire: no need to cut the bead wire equipment in advance, and put it directly; 2. From the entire tire to 1-7mm pellets, a complete production line: no secondary handling intermediate links, from material to finished product The entire packaging process; 37 people can complete all on-site operations: output/h, only 7 people;

The waste tire recycling production line crushes waste automobile tires, and the processing particle size is below 60 mesh. The waste tire recycling production line is also known as a waste tire recycling and decomposition system in the industry, which can crush and decompose waste car tires, truck tires, motorcycle tires, etc. into rubber blocks, particles, steel wires, fibers, etc., according to market output demand. Designed 1T/H-6T/H.

Before waste tires undergo thermal cracking treatment, they need to be crushed and steel wire separated to achieve the purpose of crushing, reducing capacity and reducing transportation costs. The Jeep waste tire disposal production line is mainly composed of a tire wire drawing machine, a chain conveyor, a double-shaft shear crusher, a steel wire separator, a roller screen, a magnetic separator, a belt conveyor and an intelligent detection system.

Fully automatic tire rubber recycling equipment production line Equipment name: Fully automatic tire recycling equipment Processing materials: waste tires, rubber soles, waste pipes, rubber conveyor belts and other waste rubber products Production capacity: -/h (different configurations and different output Same, subject to actual conditions) Auxiliary equipment: tire drawing machine, tire cutting machine, tire shredder, steel wire separator, rubber pellet machine, fiber separation

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231