How the Eddy Current Separator Works?

In mixed waste streams, the efficiency of separating valuable non-ferrous metals like aluminum and copper directly determines the overall profitability of recycling lines. It is against this backdrop that eddy current separators have gained widespread adoption, becoming one of the core pieces of equipment in non-ferrous metal recovery operations.

What is an Eddy Current Separator

An eddy current separator is an intelligent sorting device specifically designed for separating non-ferrous metals, typically installed after magnetic separation equipment. While magnetic separators remove ferrous metals like iron and steel, eddy current separators further isolate non-magnetic metals such as aluminum, copper, and brass from the remaining material.

It finds extensive application in aluminum can recycling, copper wire recovery, electronic waste processing, municipal solid waste sorting, and industrial solid waste recycling.

Core Working Principle

The eddy current separator operates on the principle of electromagnetic induction. Inside the equipment, a high-speed rotating permanent magnet rotor generates a strong, rapidly fluctuating alternating magnetic field. When non-ferrous metals pass through this magnetic zone, eddy currents are induced within the metal. These eddy currents create a magnetic field opposing the original field, generating a distinct repulsive force on the metal.

This repulsive force propels non-ferrous metals off the conveyor belt upon exit, creating distinct trajectories from non-metallic materials like plastics, glass, and wood chips. This enables highly efficient separation.

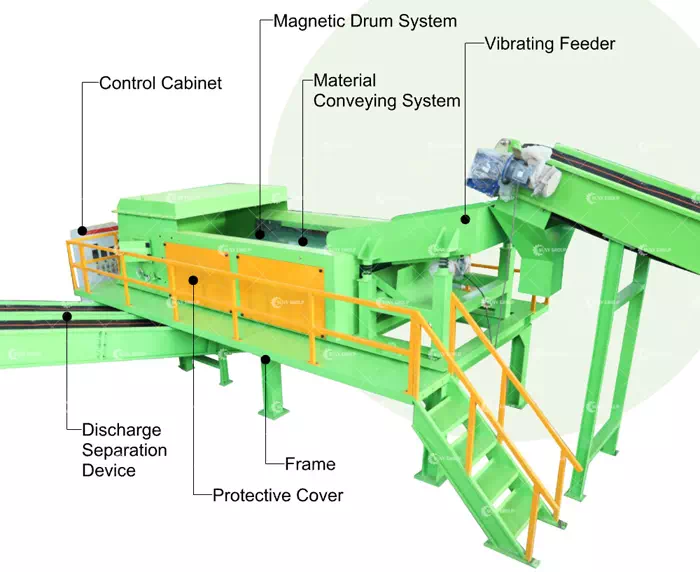

Equipment Structure

A complete eddy current separator typically comprises a high-speed magnetic rotor, wear-resistant conveyor belt, material deflector plate, support frame, and electrical control system. Some advanced models can adjust rotational speed and separation angle based on material properties to achieve optimal sorting results.

Eddy current separators offer high sorting precision, large processing capacity, minimal material damage, and significantly enhance non-ferrous metal recovery rates. Simultaneously, it effectively reduces labor costs, boosts overall production efficiency, and delivers higher economic returns for recycling enterprises.

Leveraging mature and reliable electromagnetic separation technology, eddy current separators have become an indispensable key piece of equipment in modern recycling production lines. Should you wish to learn about equipment models, technical specifications, or specific application solutions, please feel free to contact us at any time for more detailed information.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231