Used Radiators Recycling Plant

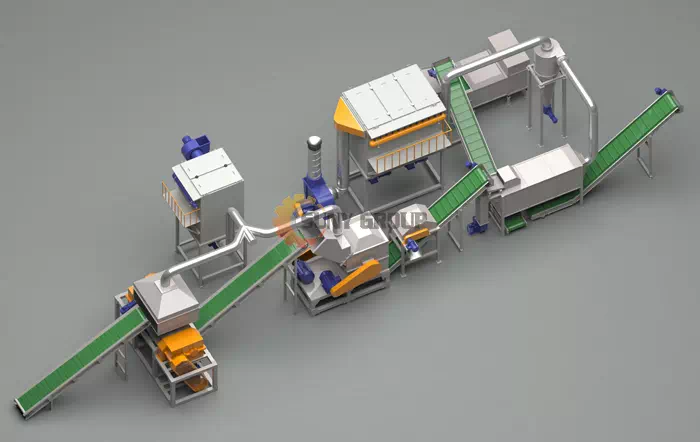

In scrap metal recycling, used radiators have long been an undervalued material stream. Because radiators are composed of copper aluminum and iron bonded together, inefficient separation directly leads to lost material value and reduced profitability. Based on years of engineering experience, SUNY GROUP has developed a professional used radiators recycling plant designed specifically to achieve high efficiency metal separation with minimal material loss and labor input.

This radiator recycling line focuses on stable operation reliable performance and high purity output making it suitable for industrial scale scrap radiator recycling applications.

Overall Process Design and Recycling Flow

The used radiators recycling plant adopts a physical crushing and precision sorting process without any chemical treatment ensuring safe operation environmental compliance and long term sustainability. Scrap radiators are first fed into the system where heavy duty shredders or shearing machines reduce the material into manageable sizes.

After primary size reduction the material enters a fine crushing stage where copper tubes aluminum fins and iron frames are fully liberated from each other. This complete physical separation is critical for achieving high purity metal recovery. The entire radiator recycling process is designed for continuous operation reducing unnecessary handling and significantly improving overall processing efficiency.

Core Equipment and Metal Separation Technology

A standard used radiators recycling plant consists of industrial shredders crushers magnetic separators eddy current separators and intelligent conveying systems. Magnetic separation is applied first to remove iron and steel components ensuring a clean ferrous output.

Non ferrous materials then pass through eddy current separation where copper and aluminum are effectively separated based on differences in electrical conductivity and material behavior. This stage represents the technical core of the radiator recycling line and allows copper aluminum separation rates to reach nearly 99 percent under stable operating conditions.

All equipment used in the scrap radiator recycling system is engineered for wear resistance low maintenance and continuous industrial use supporting long term reliable operation.

Application Scenarios and Investment Value

This used radiators recycling plant is widely applicable for scrap metal recycling centers renewable resource recovery facilities and metal processing enterprises. High purity copper aluminum and iron recovered from the system can be directly sold or reused in downstream manufacturing creating strong economic returns.

At the same time the high level of automation reduces labor dependency and helps control operating costs. As global demand for recycled metals continues to increase efficient and high purity radiator recycling has become an industry standard. This system not only answers whether radiators can be recycled but also determines how cleanly metals are separated and how much value can ultimately be recovered.

For businesses seeking a stable efficient and value driven solution for scrap radiator recycling this used radiators recycling plant represents a practical and future ready investment.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231