Solar PV panel pyrolysis recycling machinery

As photovoltaic installations continue to grow, the disposal of end-of-life solar panels has become an urgent industry need. SUNY GROUP's commercial-grade solar panel pyrolysis recycling line utilizes thermal cracking technology at its core. By decomposing the backsheet and EVA adhesive layer at high temperatures, it achieves high-purity separation of materials such as glass, silicon wafers, and solder ribbons. This solution is ideal for large-scale recycling enterprises and eco-friendly recycling plants.

Advanced Pyrolysis Technology: Enhancing Material Separation Efficiency

The core equipment is a customized pyrolysis furnace. Its sealed structure and automated temperature-control system thoroughly decompose the organic layers on the solar panel's backside at high temperatures, eliminating the inefficiency and secondary pollution associated with traditional methods that involve large-scale cutting and peeling. Post-pyrolysis exhaust gases enter an exhaust treatment system, where they undergo purification through condensation, dust removal, and active adsorption before discharge, ensuring the entire line meets environmental standards.

As EVA and backsheets are fully decomposed, glass remains intact for reuse; carrier materials like wafers and solder strips separate loosely, creating ideal conditions for subsequent mechanical sorting. This pyrolysis + mechanical separation combination significantly boosts resource recovery rates and equipment stability while reducing reliance on manual labor.

Complete Sorting System: Achieving Multi-Stage High-Purity Recovery of Glass, Wafers, and Metals

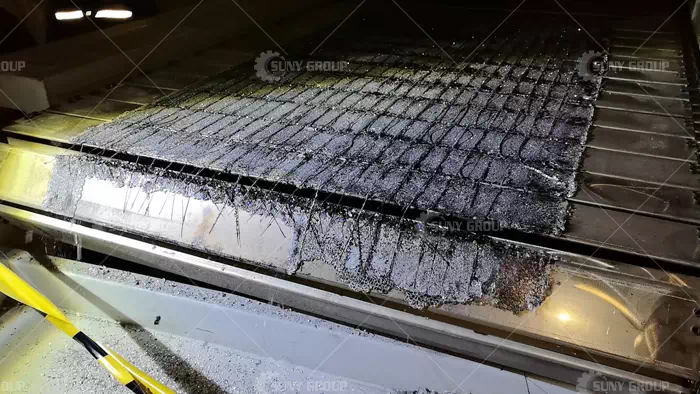

The pyrolyzed mixed material enters the downstream sorting system. The wafer sorter employs sensor recognition and precise air classification to separate intact wafers from wafer fragments rapidly. Graded screens perform layer-by-layer filtration across different particle sizes, ensuring cleaner and more uniform separation of various materials.

The density separator extracts materials with distinct density differences, ensuring wafers, glass powder, and metal particles remain unmixed. Finally, the ribbon separator platform concentrates and recovers metal ribbons, generating additional revenue from recycled metals for businesses. The entire process—from pyrolysis and screening to sorting and final output—operates seamlessly with full automation, designed for long-term stable operation.

If you're seeking a reliable solar panel recycling solution, this equipment addresses processing challenges at the source while boosting economic efficiency. For complete technical specifications, video materials, or quotes, feel free to contact us anytime. We can provide customized solutions tailored to your project scale.

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231