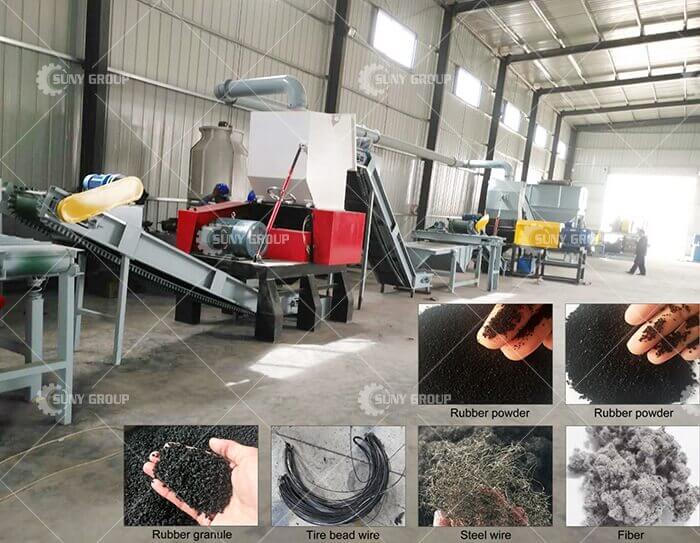

Waste tire recycling solution

The waste tire recycling production line is composed of various types of heavy equipment. Its function is to automatically separate rubber, steel wire and fiber materials in car tires, truck tires and OTR tires. This series of production lines run at room temperature without any chemical additives and will not cause secondary pollution to the environment. According to different configurations, the output of the production line ranges from 500 kg/hour to 2000 kg/hour, which is suitable for small and medium tire recycling projects.

The "modular automatic waste tire decomposition system at room temperature" adopts the normal temperature crushing method to recycle waste tires and carry out resource recycling and secondary applications. It can realize tire crushing, steel wire separation, fiber separation, and tire powder production at one time without any chemical additives. It can produce fine rubber powder of 0.42-0.12mm at room temperature, which can effectively dispose of used tires while coexisting resource recycling and environmental protection. Compared with the traditional pulverization method, the “model automatic waste tire decomposition system at room temperature” of British Empert has good energy-saving effect and is at the domestic and international advanced level. It is useful for eliminating the large-scale use of domestic and serious environmental protection and safety hazards. "Little Three Pieces" is of great significance.

The waste tire recycling production line includes the following main equipment

• Wire drawing machine-draws out the thick steel wire from the tire

• Feeding conveyor belt-transport tires to the coarse crusher

• Double shaft crusher-shred tires

• Conveyor belt-to transport tire fragments

• Steel wire separator-crush the tire fragments to 15-20mm particles to separate the rubber from the steel wire

• Magnetic separator-separate steel wire in rubber

• Conveyor belt-convey rubber granules

• Crusher-further crush the rubber particles to 1-4mm to separate the rubber from the fiber,

Remove some fibers

• Vibrating screen-sorts the rubber particles according to the particle size and removes part of the fiber

• Fiber separation system-separation of remaining fibers

• Magnetic sorting machine-remove the small wires that may be left in the place

• Bagging system

• Central dust collector-collect dust and fiber generated by the production line

• Control electric box

Recommend products

CONTACT US:

If you have any requirement or suggestion, please fill in the form and send to us, thanks!E-mail:sunymachine@gmail.com | Whatsapp:+8613674945231